|

Selaco possesses 4 extrusion

lines extruding various shapes of aluminium section with different alloy

and temper. All presses are equipped with on-line billet saw or hot-shear

in order to optimise the input material. While all 4 presses are Taiwan

made (Cheng Hua (2200 Ton, 880 Ton), Yuan Shang (1800 Ton), Jin Jie (1375 Ton)), the associate equipment such as billet heater, puller,

ageing oven are of western origin. These include Granco-Clark and Gerref

of USA, Mechatherm of UK and Furnace Engineering of

Australia. |

|

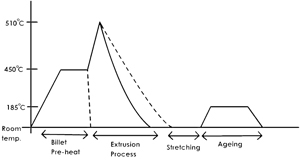

Aluminium extrusion process is a

heating cycle. Control of temperature at various stage is essential. At

the start of the process, aluminium billets are preheated up to about

450°C ~ 480°C while the die is heated to 430°C. As the billet is extruded

throught the die orfice, the extruate leaves the die at 510°C or higher.

Depending on the temper requirement (T5 or T6), forced air-cooling or

water quenching is employed to cool the extruate. Stretching is then

carried out at room temperature, straightening the extrusion to the

require straightness. After cutting to customer require length, artificial

ageing is done at about 185°C ~ 205°C for 3 to 6 hours depending on temper

requirement. During the ageing process, magnesium silicide (Mg2Si) Precipitates from solid solution at elevated

temperature to harden and strengthen the extrusion. This process is also

known as Precipitation Hardening. |